Page 25 - USSC Catalog

P. 25

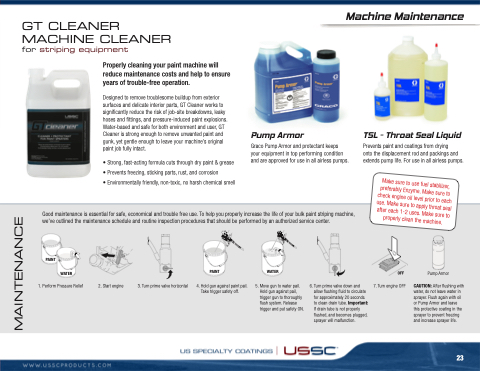

GT CLEANER MACHINE CLEANER

for striping equipment

Properly cleaning your paint machine will reduce maintenance costs and help to ensure years of trouble-free operation.

Designed to remove troublesome buildup from exterior surfaces and delicate interior parts, GT Cleaner works to significantly reduce the risk of job-site breakdowns, leaky hoses and fittings, and pressure-induced paint explosions. Water-based and safe for both environment and user, GT Cleaner is strong enough to remove unwanted paint and gunk, yet gentle enough to leave your machine’s original paint job fully intact.

• Strong, fast-acting formula cuts through dry paint & grease • Prevents freezing, sticking parts, rust, and corrosion

• Environmentally friendly, non-toxic, no harsh chemical smell

Machine Maintenance

RECOMMENDED SERVICE & INSPECTION

Good maintenance is essential for safe, economical and trouble free use. To help you properly increase the life of your bulk paint striping machine, we’ve outlined the maintenance schedule and routine inspection procedures that should be performed by an authorized service center.

PAINT

1. Perform Pressure Relief

Make sure to use fuel stabilizer, preferably Enzyme. Make sure to check engine oil level prior to each use. Make sure to apply throat seal after each 1-2 uses. Make sure to properly clean the machine.

WATER

PAINT

4. Hold gun against paint pail. Take trigger safety off.

WATER

5. Move gun to water pail. Hold gun against pail, trigger gun to thoroughly flush system. Release trigger and put safety ON.

OFF

7. Turn engine OFF

Pump Armor

CAUTION: After flushing with water, do not leave water in sprayer. Flush again with oil or Pump Armor and leave this protective coating in the sprayer to prevent freezing and increase sprayer life.

2. Start engine

3. Turn prime valve horizontal

6. Turn prime valve down and allow flushing fluid to circulate for approximately 20 seconds to clean drain tube. Important: If drain tube is not properly flushed, and becomes plugged, sprayer will malfunction.

Pump Armor

Graco Pump Armor and protectant keeps your equipment in top performing condition and are approved for use in all airless pumps.

TSL - Throat Seal Liquid

Prevents paint and coatings from drying

onto the displacement rod and packings and extends pump life. For use in all airless pumps.

MAINTENANCE

23